The machine is made up by stroma dissolution pot,vacuum emulsification blender, hot water pot, cam rotor pump, vacuum pump, hot water sanitation pump, hydraulic system,automatic feeding material system,electrocontrol system.

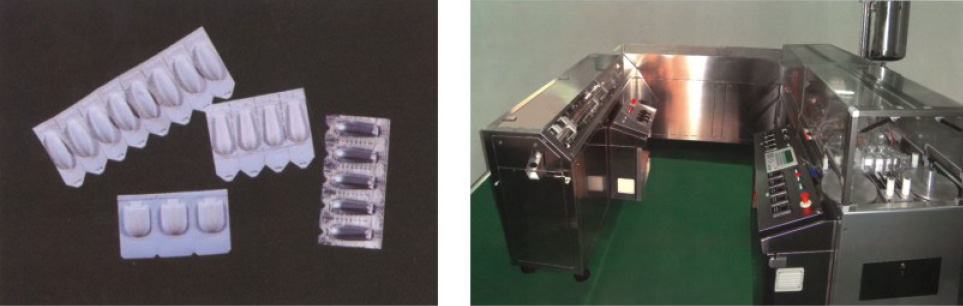

The machine is used to produce the suppository medicine and specially used to emulsification of oil stroma, cream stroma, solubility material and pectic material with high content of solids.

The machine has easy operation,steaay capanly,goud homogeneity, high efficiency, reasonable structure, small volume and high automation level and easy cleaning.

The machine has triple blender,hydraulic lift cover,high-speed homogeneity blender (Speed is 0-180Or/min,frequency speed regulation) and low-speed scraper blender ( Speed is 10-7Or/min,frequencyspeed regulation). Fast-cutting vortex emulsification blender is used in the homogeneity part, which can scrape in a low speed and automatically blend and snuggle up to the bottom and wall of boiler. In the course of mixing the cam rotor pump let the material move in the way of outer circle in order to emulsify the material.The machine makes the material mix into the vessel of package machine by automatic hydraulic control feeding material.The machine draws powder material by the way of vacuum in order to prevent the powder flying. The whole working procedure is operated in the condition of vacuum in order to prevent the material coming into being bubble after high-speed blending and reach the request of sanitation and asepsis.CIP cleaning system is equipped in this system.The contact part of vessel and material is made from SUS316Lmaterial.Mirror finish of the inside surface is 300EMSH.ln order to ensure the stabilization of the control, the electro-control part is the products of Germany Siemens Company,the button is produced by Japan Fuji Company, the transducer is the product of Japan Matsushita Electric lndustries and the vaccum pump is the product of Siemens Company. The machine is made completely according to the GMP request, which is the most advanced and most perfect suppository production equipment.

| MODEL | EFFECTIVE CAPACITY | EMULSIFY | AGITATOR | OUTSIDE DIMENSION | THE MERIT RATE (KW) | |||||

| KW | min/r | KW | min/r | LENGTH | WIDTH | HEIGHT | MAX H | |||

| KRSRJ-100 | 100 | 3 | 0-1700 | 1.5 | 10-70 | 2400 | 2360 | 2200 | 2800 | 10.5 |

| KRSRJ-150 | 150 | 4 | 0-1700 | 1.5 | 10-70 | 2450 | 2375 | 2200 | 2900 | 11.5 |

| KRSRJ-200 | 200 | 4 | 0-1700 | 1.5 | 10-70 | 2500 | 2380 | 2200 | 2900 | 11.5 |

| KRSRJ-350 | 350 | 5.5 | 0-1700 | 2.2 | 10-70 | 2800 | 2600 | 2550 | 3400 | 16 |

| KRSRJ-500 | 500 | 5.5 | 0-1700 | 2.2 | 10-70 | 3700 | 3500 | 2600 | 3500 | 19.5 |

Feedback

QR code

Feedback

Work time:

8:00-17:00

Feedback